Weyermann ®

Inside Weyermann ®

with Axel Jany

The Weyermann ® video series provides you with exciting insights from their red and yellow Weyermann® world. You can expect information about their products, technical questions and many other topics relating to malt and brewing.

Say hello to their expert Axel Jany, Weyermann® team leader international customer consultants!

For this, temperatures are driven in the roasting drums, which mimic the maize in the brewery.

Thus the alpha and beta-amylase will attack the strength and release the sugars, which are later brought to caramelize by thermal treatment.

Depending on the intensity of caramelization, different flavors and aromas are formed: from salty and biscuit-like to caramel and nut flavors.

Introducing Weyermann® Acidulated Malt: The Perfect Addition to Your Brew

We are thrilled to present to you Weyermann® Acidulated Malt. With a pH level of 3.3 – 4.5, this speciality malt is ideal for lowering the pH of your wort. By doing so, it enhances mashing and fermentation, leading to a more refined beer flavour.

This malt boasts an EBC value of 2.5 to 12.0 and the addition of up to 5% of Weyermann® Acidulated Malt can boost the flavour stability of your beer. It is highly recommended for use with hard brewing water and is particularly effective for Pilsner, Ales, light beers, wheat beers, and draft beers.

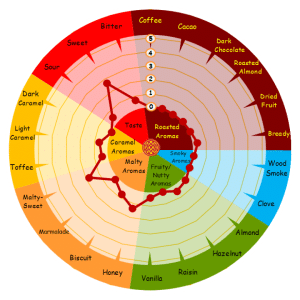

For naturally sour beers, we recommend adding up to 10% for that perfect characteristic taste, which brings hints of dried fruits. The sensory impression is completed by nuances of vanilla, hazelnut, and honey. Overall, Weyermann® Acidulated Malt is an excellent choice to harmoniously complete the taste of your beer.

Weyermann® Beech Smoked Barley Malt, which continues the Bamberg-smoked beer tradition. In the 19th century, all malt was traditionally dried on an open fire, giving the beer a smoky taste.

Weyermann®’s sensory experts describe the Beech Smoky Barley Malt as having a honey-like sweetness and smoky aroma with recognizable flavours of clove, candy, caramel, vanilla, cocoa and breadcrumb. This malt is ideal for smoked beers, lagers, “Kellerbiere”, speciality smoked beers, and wheat beers, with up to 100% added content. A rustic “slightly smoky” taste can be achieved with the addition of 10-20% malt.

Weyermann® Carafa® is the perfect complement to dark smoked beers, with a colour range of 4.0 to 8.0 EBC. For those seeking an example of a successful smoked beer, give our Weyermann® “Schlotfegerla®” a try – always available at the Weyermann® Living & Drink Shop.

Did you know that smoked malt is also used by many distilleries, and not just for dark beers? In fact, for a lighter version of smoked beer, check out the Bamberger Hofbräu® Rauch, another offering from Weyermann®.

Join us in continuing the tradition of smoked beer with Weyermann® Beech Smoked Barley Malt.

The Weyermann® Caramunich® is perfect for classic “Bavarian” dark beers. Depending upon the addition (1-5% for light beers, 5-10% for dark beers), our Weyermann® Caramunich® delivers a robust, full and round flavour in dark and brown beers, Festival beers, Oktoberfest beers, Bock beers, non-alcoholic malt beverages, nutritional beers, Schankbier and light beers.

Weyermann® beer sommeliers describe intense malt aromas, a distinctive caramel flavour with notes of pastry, bread crust and cocoa in Weyermann® Caramunich®. You can also notice a subtle flavour of raisins, coffee and almonds. Weyermann® Caramunich® allows for a brilliant play of colour between dark copper and amber brown to maroon brown. Thanks to several Weyermann® special malts, there’s no limit to brewers’ imagination as they craft their recipes. This malt comes in three categories: I, II and III. The Weyermann® Caramunich® I, has an EBC value between 80-100, Type II between 110-130 and Type III between 140 and 160.

Weyermann® Isaria 1924®. An order only item from Charles Faram, which means that it’s not on our shelves but we can order it for you.

Isaria was first bred in 1912 by Ackermann, a German barley breeder since 1903, and it was officially accepted for brewing in 1924 becoming a European success variety.

Isaria was in the brewing barley program until 1963, making it one of the oldest commercial spring barley varieties in the world.

The impressive influence of Isaria and its preference by German brewers during the first half of the 20th century were enough reasons for Weyermann® to grow and malt Isaria in the 21st century again.

Now, nearly 100 years later, Isaria adds its flavour to beers once again as a Weyermann® exclusive heirloom variety: Isaria 1924®, giving beers a malty, yet not so sweet taste and a soft unique nutty aroma.

Back then malts had had a darker colour, and also Weyermann Isaria 1924® with its colour of 7-9 EBC or 3.1 – 3.8 Lovibond shows this lineage.

Isaria1924® is perfect for beers such as Zoigl, Keller, unfiltered Lager as well as Festbier.

Top malt is an undermodified malt to improve foam stability. The modern version of the top malt is our Weyermann® Carapils®. In the USA, our Weyermann® Carapils® is registered as Weyermann ® Carafoam® and is distributed as Carafoam ® by our partner BSG Craftbrewing.

The Weyermann® Carafoam® was first developed and registered in 1908 by Weyermann ® under the name Carapils®. It’s a 115 year old, modern product and a great way to achieve a consistent “top malt result” with a nice foam and light beer color.

The Weyermann® Carafoam® and the Weyerman® Carahell®, which are slightly darker and provide more body, are great technical malts that can be added to the base malt for Pilsner and Helles.

To make this product, the green malt is transferred directly from the germination box into the roasting drum, so that the amylases already formed during germination can decrease the strength.

For this, temperatures are driven in the roasting drums, which mimic the maize in the brewery.

Thus, the alpha and beta-amylase will attack the strength and release the sugars that will be caramelized later through thermal treatment.

Depending on the intensity of caramelization, different flavors and aromas are formed: from greasy and cookie-like, to caramel and nutty flavors

Water hardness occurs when water penetrates through soils and/or aquifers.

The geological underground is therefore strongly responsible for the geographical distribution of the water hardness.

For example, you can ask the city works about the hardness of your city’s water.

Information on the hardness of the city water is crucial for the burner because he will or will not carry out water treatment based on this information.

Despite the knowledge of the municipal corporation, it is useful to analyze the hardness of the city water within its operation in order to determine the exact hardness before and after the water hardening.

If the city water exceeds a hardness of 3°dH, the water used to lower the distillate / spirits must be hardened.

If the “average water” (more on that in the next episodes of our FAQ Tuesday series) is not hardened, hardnesses form in the distillate.

Philipp Schwarz, Weyermann® Distille team leader, explains today what you mean by hardening in distillates / spirits.

As already explained last week, the geological underground is strongly responsible for the hardness of the water.

Groundwater from plaster layers can produce high concentration

Be responsible for magnesium and calcium ions in city water.

These magnesium and calcium ions are insoluble in a mixture of alcoholic water, such as a beer fire, and cause so-called hardness.

Therefore it is important to harden city water before burning.

In the past weeks, we talked to Philipp Schwarz, our Weyermann® team leader distillery, about the terms surrounding water for distillates/spirits.

In this context, we should answer today what the abbreviation “°dH” is all about.

The abbreviation °dH denotes the degree of German hardness and is used in connection with the total hardness of water, which denotes the sum of the eartalkali calcium and magnesium (rare strontium and barium) present in the water.

The hardness is now indicated in mmol/l or mol/m3.

The °dH unit is outdated, but still useful in practice.

We want to provide our customers with the best quality, no matter what the weather conditions may be on the way from Bamberg to your brewery.

Recently we focused on Sinamar® and examined our RME when kept under freezing temperatures.

The tests have shown that frozen samples (frozen over two weeks) do not differ from the samples kept at ambient temperatures of the same batch. This was confirmed by our laboratory, as well as our trained taste panel members.

No differences between the frozen and reference samples were noticed in regards to taste, quality or solubility behaviour!

As an additional plus, we can say that our canisters can withstand the most adverse transport temperatures, even at -18 ° C.

In order to cope with the growing market of non-alcoholic beer, Fermentis searched for and found a suitable yeast stem for producing non-alcoholic beers.

The dry yeast SafAle® LA-01 is derived from Saccharomyces cerevesiae var. Knights of Hefestamm.

As the exclusive distributor for fermented yeast in Germany and Austria, the Maltzfabrik Weyermann® has helped in the development of this yeast with fermentation trials in our experimental brewery.

The know-how of our brewing masters, the different malts and parameters have been incorporated into the research.

The peculiarity of this yeast is that it cannot use either maltose or maltotriose and only simple sugars such as glucose, fructose or sucrose are metabolism. As a result, beer with an alcohol content of less than 0,5% vol with a 7° plateau result in regular spices.

However, the complete process of fermentation does not have to be without fermentation by-products that sometimes give beer its character.

In addition, this yeast is also suitable for light beers, since even with higher spices, only low alcohol content is achieved.

Important when using this yeast is the final pasteurization, or run through a KZE, to prevent possible degeneration. The target is 100 PE.

The dosage is indicated at 50 to 80g/hl beer.

A beautiful example is our non-alcoholic beer Weyermann® #99, which was brewed with this yeast.

If the brewer wants to spice up your beer and emphasize its taste and aroma, as well as push the color into the copper-red or darker area, then our Weyermann® special malts, which are generally divided into two categories (roast and caramel malts), are used.

Roasted malt represents the very dark, roasted malt products that are responsible for the darkening of the beer color.

These will be available in very small quantities (max. 5-6%) of the maize to create, for example, an inferior dark beer or a superior stout.

In addition to the color, the Weyermann® roast malts create pleasant roast, coffee and chocolate notes.

There are many different types of malt. Among the large variety of brewing malts, the base malts are used as, you guessed it already, the base of your beers.

Base malts include all components required to make a beer wort and ultimately to brew a beer from it.

The base malt should show an enzyme-strong potential, which is able to break down high molecular weight compounds – especially the starch – and produce fermentable sugars from it and provide other nutrients to the yeast.

Furthermore, the malt husks serve as a natural filter during the lautering process to achieve a clear wort runoff.

Finally, a base malt gives the basic colour of a beer: usually situated in the middle of the colour spectrum (blond and yellow).

Wheat is a general term that contains many grains of the genus Triticum. There is therefore a relatively long list of wheat varieties that differ in their genetic composition and therefore in their properties and use in the food industry.

Since the genetic classification of wheat is too complicated for daily use, it is more common to categorize different types of wheat according to their rheological characteristics, global production volume and food applications.

The two most commonly used and accepted types are hard wheat

and soft wheat.

Wheat contains very high protein content, which makes it a perfect ingredient for pasta dough. Soft wheat is the most commonly used wheat variety in the food industry, which is often used for baking due to its significantly lower protein content.

This is why soft wheat is the best wheat variety to make sweet and soft bread and to brew salty and tasty wheat beers.

Therefore, Weyermann® works exclusively with local wheat varieties from locally grown, which are milled to light, dark, caramel-colored and roasted wheat mills.

Further differentiation criteria were adopted by the food industry to also classify brewing wheat varieties. In fact, the terms “red” and “white” (the difference can be found in the US and Canada) were considered useful to categorize wheat varieties when brewing.

However, it does not present a reliable classification method, as Weyermann® can adjust the final wheat malt color either on the tar or in the roasting drums depending on the desired expression.

Foam represents a very important visual feature of beer in many beer-drinking cultures. Fundamentally, the beer foam is a complex system called dispersion, in which a gas (CO2) is dispersed in a liquid (beer).

The beer head retention is naturally stabilized by high-molecular proteins.

These enhance the stability of the CO2 bubbles and prevent and delay their collapse.

Malt is a natural source of proteins. By adapting the malting process, it is possible to keep the proteins to remain high-molecular.

This is the case of the Weyermann® Carafoam® / Carapils®, a malt product that is just slightly modified and carefully germinated and dried, so it provides the wort with high-molecular proteins.

Being smoothly caramelized in rotating drums, Carafoam® / Carapils® improves the head retention by giving body and malty taste to the beer at the same time. All done naturally by our skillful maltsters.

The second product we produce with foam improvement characteristics is Carahell®.

Carahell® is produced with a darker color and a more intense malty taste in the rotating drums for the usage in darker beers than the light colored Carapils®/Carafoam®.

To improve the beer foam characteristics after pouring a beer, a minimum of 5% of either Carapils® or Carahell® is recommended. To extend the head retention, a minimum of 10% will be required.

Happy brewing!

At Weyermann® we use only new and high-quality pallets for the worldwide shipping of our malt.

All of our pallets are sourced from sustainable forestry and certified according to Forest Stewardship Council (FSC) criteria. The seal of quality confirms that all wood meets the social, economic and environmental needs of present and future generations. Thus forests will remain sustainable.

In addition, the pallets are chamber-dried and IPPC certified.

According to the International Plant Protection Convention, the wood is gently heated and prevents such pests and the emergence of wood diseases. Until they are used, the pallets are stored moisture-proof in our halls.

By using only new pallets, we ensure that our malt remains free of foreign substances and, when exported to over 135 countries, the further travel of unwanted organisms in wood is prevented.

In this way, we can close the circle of our high-quality Weyermann® philosophy, which extends from the selection of grains to the entire production of our high quality products to the packaging in our Weyermann ® malt ambassadors with the renowned aroma protection.

Yes, every malt bag from Weyermann® has a best-before date of 18 months. The aroma profile of our over 80 different malts does not change significantly in this time, as we could find out in the weekly tasting rounds from our experts of the quality assurance regarding the flavor stability of our specialty malts.

The most important reason for this great flavor stability of our malts are our high-quality Weyermann® bags, our red printed ambassadors – disposable bags of extra tear-resistant PP (polypropene) with a waterproof PE (polyethene)-inlet.

The PE-inlet ensures optimal aroma protection.

All bags are folded up at the top, sewed up twice (!) with red and white thread and thus provided with a freshness seal.

We wish all our customers everywhere in the world “happy brewing” with our fresh, tasty Weyermann® specialty malts!

The “I-nigma” barcode reader is a free smartphone application which works very well to download the batch malt analysis by scanning the analysis code from Weyermann® bags.

In some operation systems the analysis pdf is stored in the “download” folder.

For I-OS: “IBooks” can be used to store the analysis.

Analysis can be printed or forwarded by email, WLAN or Bluetooth now.