Quality

From Farm to Faram - best quality practices

01

Grower Assistance

We recognise the importance of ensuring the best quality practices from Farm to Faram. Working with growers throughout the year on pesticides, fertilisers and sustainability.

02

Harvest

Discussing optimum picking times, and quality of samples, stock and operations.

03

Sampling & Certification

Hop bales are sampled and collected from

the farms

04

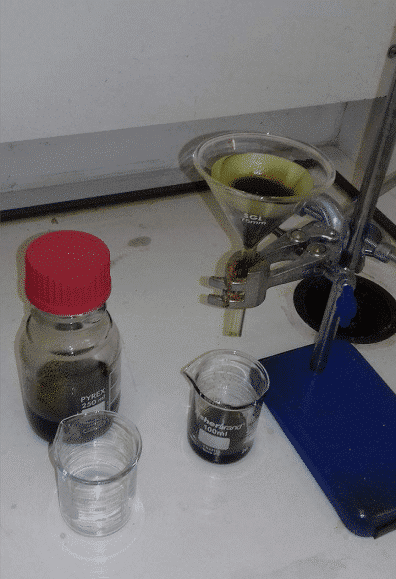

Pesticide Residue Testing

Testing samples are sent to independent certified laboratories to check compliance with approved residue levels

05

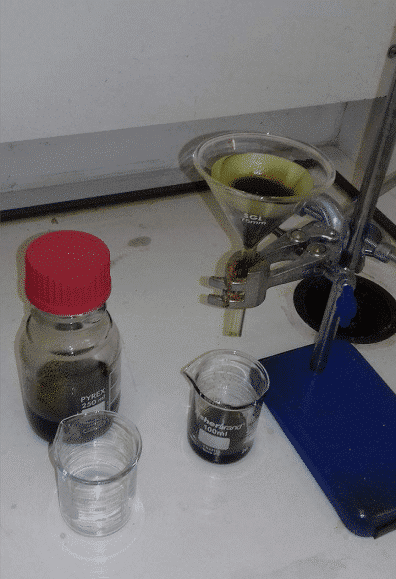

Alpha Testing

In our on-site laboratory, bale samples are tested using LCV analysis according to EBC (European Brewing Convention) method 7.4.

06

Delivery To Stores

Hops bales are delivered to Charles Faram 0° stores in the UK and Yakima

07

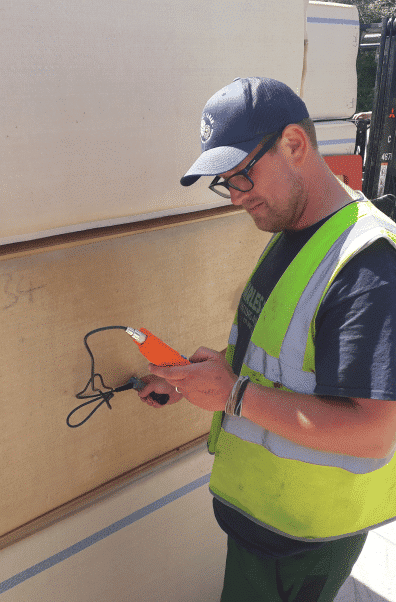

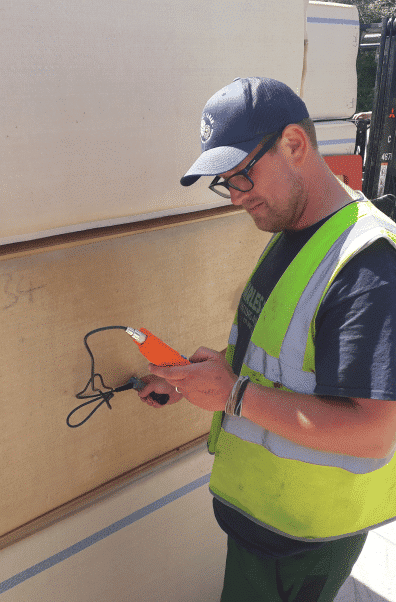

Moisture Testing

Bales are tested with a moisture meter to check that they are below 12% moisture

08

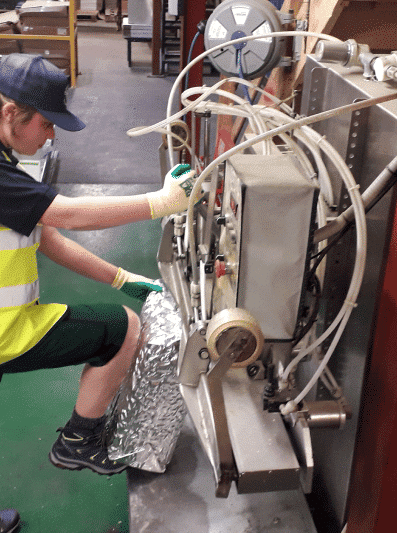

Grading

Faram’s inspect samples for quality and grading. At this point, the hops are accepted or rejected

09

Shipping

Our US and New Zealand hops are 100% cold from the day they are picked. Our US Yakima facility and our partners at New Zealand hops are staging points for quality checks and the safe onward shipment of hops to the UK

10

Customer Selections

Brewers make batch selections for their next hop contract

11

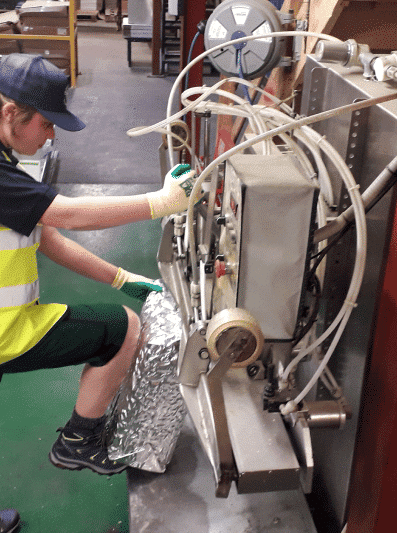

Packaging

Our cartons are made from 100% recycled material and are also recyclable. Our foils have to be lightweight and easy to handle whilst preventing the ingress of moisture, oxygen and light, yet strong enough to keep the packs intact

12

Storage

Many brewers take delivery of all their hops for the year as soon as they are ready, but most are stored at Charles Faram 0° stores for call off or spot sales

13

Delivery To The Customer

Charles Faram hops are distributed to breweries all around the world. Partners are reviewed regularly to ensure the best service and rates available

01

Grower Assistance

Working with growers throughout the year on pesticides, fertilisers and sustainability.

02

Harvest

Discussing optimum picking times, and quality of samples, stock and operations.

03

Sampling & Certification

Hop bales are sampled and collected from

the farms

04

Pesticide Residue Testing

Testing samples are sent to independent certified laboratories to check compliance with approved residue levels

05

Alpha Testing

In our on-site laboratory, bale samples are tested using LCV analysis according to EBC (European Brewing Convention) method 7.4

06

Delivery To Stores

Hops bales are delivered to Charles Faram 0° stores in the UK and Yakima

07

Moisture Testing

Bales are tested with a moisture meter to check that they are below 12% moisture

08

Grading

Faram’s inspect samples for quality and grading. At this point, the hops are accepted or rejected

09

Shipping

Our US and New Zealand hops are 100% cold from the day they are picked. Our US Yakima facility and our partners at New Zealand hops are staging points for quality checks and the safe onward shipment of hops to the UK

10

Customer Selections

Brewers make batch selections for their next hop contract

11

Packaging

Our cartons are made from 100% recycled material and are also recyclable. Our foils have to be lightweight and easy to handle whilst preventing the ingress of moisture, oxygen and light, yet strong enough to keep the packs intact

12

Storage

Many brewers take delivery of all their hops for the year as soon as they are ready, but most are stored at Charles Faram 0° stores for call off or spot sales

13

Delivery To The Customer

Charles Faram hops are distributed to breweries all around the world. Partners are reviewed regularly to ensure the best service and rates available